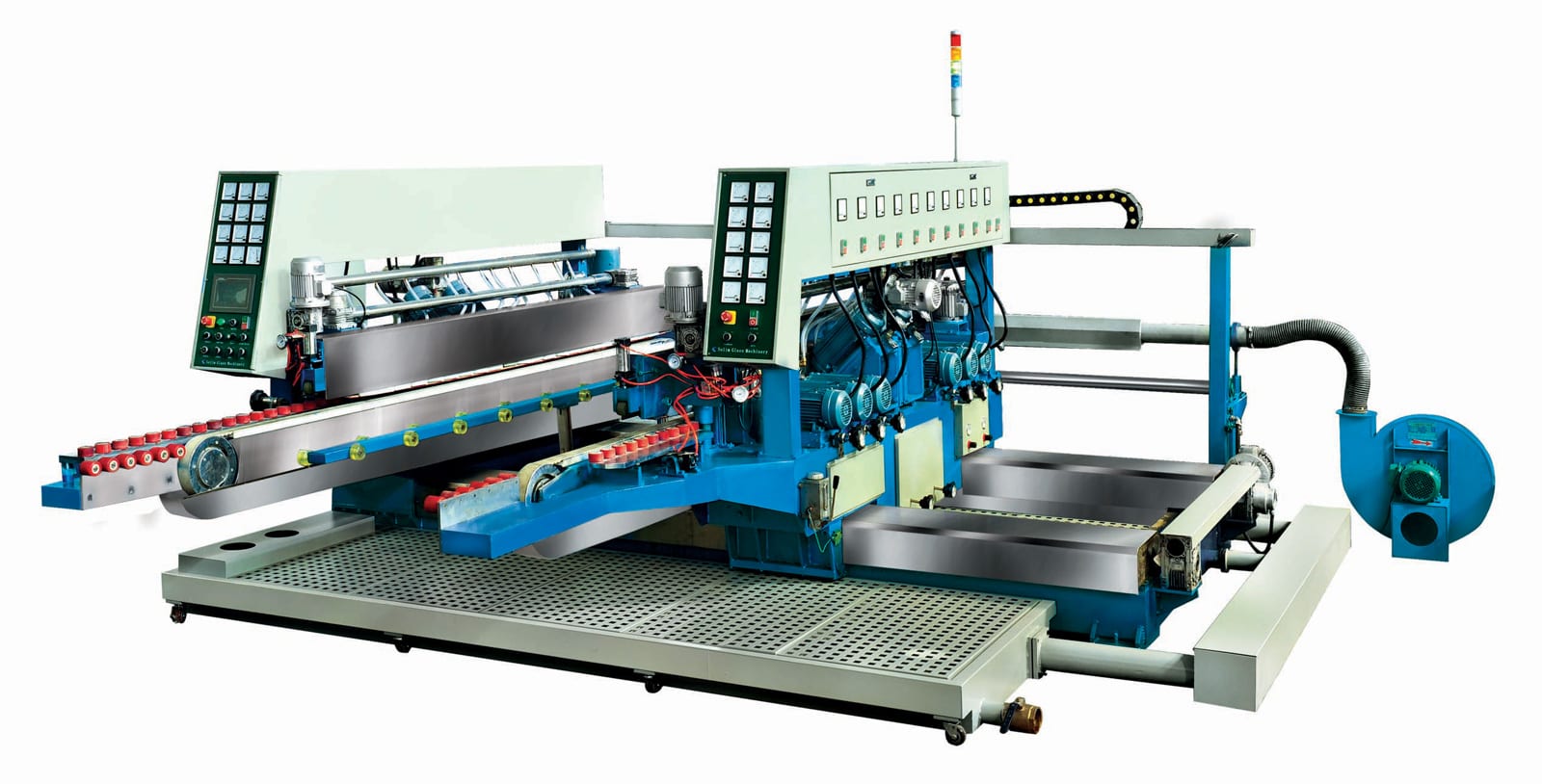

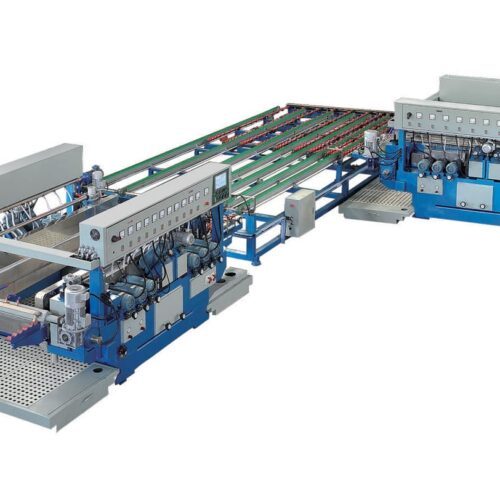

SDE Double Edger

Description

The SDE Double Edger Glass Machine is a state-of-the-art device designed to provide precision and reliability in glass edging. This continuous-running machine features a timing belt for the upper and bottom conveyor and employs a double L/M roller guide for the movable table, ensuring smooth operation. The machine’s glass feeding speed can be manually adjusted, offering a range from 0.5m/min to 5.0m/min. It boasts an impressive grinding precision, with width precision less than 0.5mm and diagonal precision within ±0.5mm. Additionally, the machine is equipped with an automatic squaring device and is capable of processing two parallel flat edges with arris plus corner-cut.

One of the standout features of the SDE Double Edger is its spindle configuration. Each side has 10 grinding spindles plus 1 corner-cut, which use ABB special AC motors. The grinding spindles come with diamond and resin wheels of different sizes and grain types, ensuring precise and consistent edging results. The polishing wheels are lifted pneumatically, providing an added layer of control during the edging process.

The machine accommodates a wide range of glass thicknesses, from 4mm to 30mm, and can handle a minimum glass width of 300mm. The maximum glass width varies based on the specific model, with the SDE2245 accommodating up to 4500mm, and the SDE2225 up to 2500mm. Thickness and width adjustments are driven by an AC motor with encoder, and the whole process is controlled by a dual-PLC system to streamline operation.

The SDE Double Edger also prioritizes user experience, featuring a man-machine monitor for setting, controlling, and displaying processing parameters. Plus, its working table is set at a comfortable height of 850mm. Depending on the model, the machine’s total weight ranges from 6000kg to 8000kg. All these features combined make the SDE Double Edger a reliable and efficient choice for all your glass edging needs.

- Overall dimensions:

- SDE2245: 6500 X 4700 X 1800mm (Includes circulatory water tank)

- SDE2236: 5600 X 4700 X 1800mm (Includes circulatory water tank)

- SDE2230: 5000 X 4700 X 1800mm (Includes circulatory water tank)

- SDE2225: 4500 X 4700 X 1800mm (Includes circulatory water tank)

- Operating method: Continuous running and manual feeding

- Upper/bottom conveyor: Timing Belt

- Movable table droved by double L/M roller guide and double roller screw with lubrication system

- Water pump: AC motors 0.25 kW 2 sets

- Glass feeding speed adjustment: Manual adjusts the converter frequency adjuster on the controlled panel and speed displayed

- Grinding precision: Width precision<0.5mm (1000mm) Diagonal precision<±0.5mm (1000X1000mm)

- Machine is equipped an automatic squaring device

- Processed profile: Two parallel flat edge with arris plus corner-cut

- Power supply: 3-Phase, Voltage: 415V/380/220V, 50/60Hz, as required; Total power: 45 kW

- Grinding spindles: Each side 10 spindles+1 corner-cut

- Glass thickness: 4mm-30mm

- Minimum glass width: 300mm

- Maximum glass width:

- SDE2245: 4500mm

- SDE2236: 3600mm

- SDE2230: 3000mm

- SDE2225: 2500mm

- Glass feeding speed: 0.5m/min-5.0m/min adjustable (by using converter)

- Thickness and width adjustment: AC motor with encoder and displayed controlled by PLC. Adopt two PLC for machine controlling to lessen the cable quantity.

- A man-machine monitor is for setting, controlling and displaying the processing parameter

- Working table height: 850mm

- Wheels and grinding spindle configuration:

- All wheels except corner-cut are Cup-Shape wheels; Corner-cut wheel is peripheral wheel

- All grinding motors except corner-cut use ABB special AC motor

- Polishing wheels are lifted pneumatically. Each side spindle configuration:

- Pos.1. Diamond 150mm, grain size #100 segment type, 2.2kW for flat edge

- Pos.2. Diamond 150mm, grain size #240, 2.2kW for flat edge

- Pos.3. Resin 150mm, grain size #240, 2.2kW for flat edge

- Pos.4. Resin 130mm, grain size #150, 1.75kW for upper arris

- Pos.5. Polishing 130mm, 10S40, 1.75kW for upper arris

- Pos.6. Resin 130mm, grain size #150, 1.75kW for bottom arris

- Pos.7. Polishing 130mm, 10S40, 1.75kW for bottom arris

- Pos.8. Resin 150mm, grain size #320, 2.2kW for flat edge

- Pos.9. Polishing 150mm, 10S40, 2.2kW for flat edge

- Pos.10. Polishing 150mm, CE3, 1.5kW (Low speed) for flat edge

- Pos.11. Diamond 75mmX22mmX40mm, grain size #180, 0.17kW for corner-cut

- Total weight:

- SDE2245: 8000kg

- SDE2236: 7500kg

- SDE2230: 7000kg

- SDE2225: 6000kg