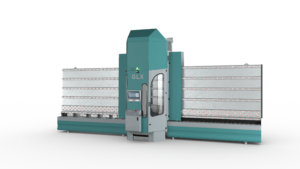

CNC Vertical Glass Grinding & Arrising Machine

Showing the single result

Vertical CNC-guided system for grinding and polishing flat glass

Key Advantages

- This vertical grinding machine is for grinding and polishing glass sheets and shapes with at least one straight edge in just one clamping process-ensures maximum precision and dimensional accuracy

- Can be used as a stand-alone device or integrated into a combiFIN processing line

- Edge-parallel tracking of the grinding head through highly dynamic water cushion system

- Manual quick-change system for tool packs (automatic 12-fold changer available as an option)

- Uncomplicated maintenance and easy access to all components

- Compact construction- all components required for operation are integrated in the device (control cabinet, vacuum tank)

- Internal cabling largely protected and integrated in the device

- Including lubrication, tool extractor and polishing wheel grooving unit

Function and Sequence

- Creation of process drawing for glass sheet with corresponding geometrics directly on the machine or optional import via the network

- Automatic data splitting as soon as drilled holes or cut-outs are also included in the processing…with existing line network with combiFIN- data transfer to the processing machine

- Positioning of the cut glass sheet on the machine in-feed

- Release of the glass sheet by the operator (during manual operation)

- Automatic check for availability of required processing tools

- Automatic detection of the reference edge by the machine, even when processing shapes or radii

- Automatic transfer into the machine compartment and execution of edge processing

- At the end of the processing cycle, the glass sheet is automatically transported out of the processing cabin or passed on to the downstream machine

Design

- Glass Transport: by means of two-part feed system- vacuum suction cup and transport rollers with slip clutch

- Tool diameter nominal(mm): 80 (3 tools)

- Angle (degrees): 7

- Glass running height(mm):600

Performance Data

- processing size (mm): 3210×2000

- processing size (mm): 470×180

- Glass thickness min (mm): 4

- glass thickness (mm): 12

- glass weight (kg/m): 100

- Grinding speed up to 15m/min

- Transport speed up to 30m/min

- Machinability of round corners or butted edges without loss of cycle time

- Machinability of all rectangles and shapes (prerequisite: a straight set-up edge)

Operating data and installation Requirements

- Connected load (kW):26

- pre-fuse 50 Amp

- TN-S power network

- Compressed air connection 6 bar, 130 l/min

- Water connection 2×1 inch (pure water + circulation)

- Water consumption (water treatment-approx. (l/h): 1500

- Dimensions (mm): 7640 x 3130 x 3830 (width, depth, height)

- Total Weight (kg): 6600 (ready for operation)

- Can be used as a standalone device or integrated into a combiFIN processing line