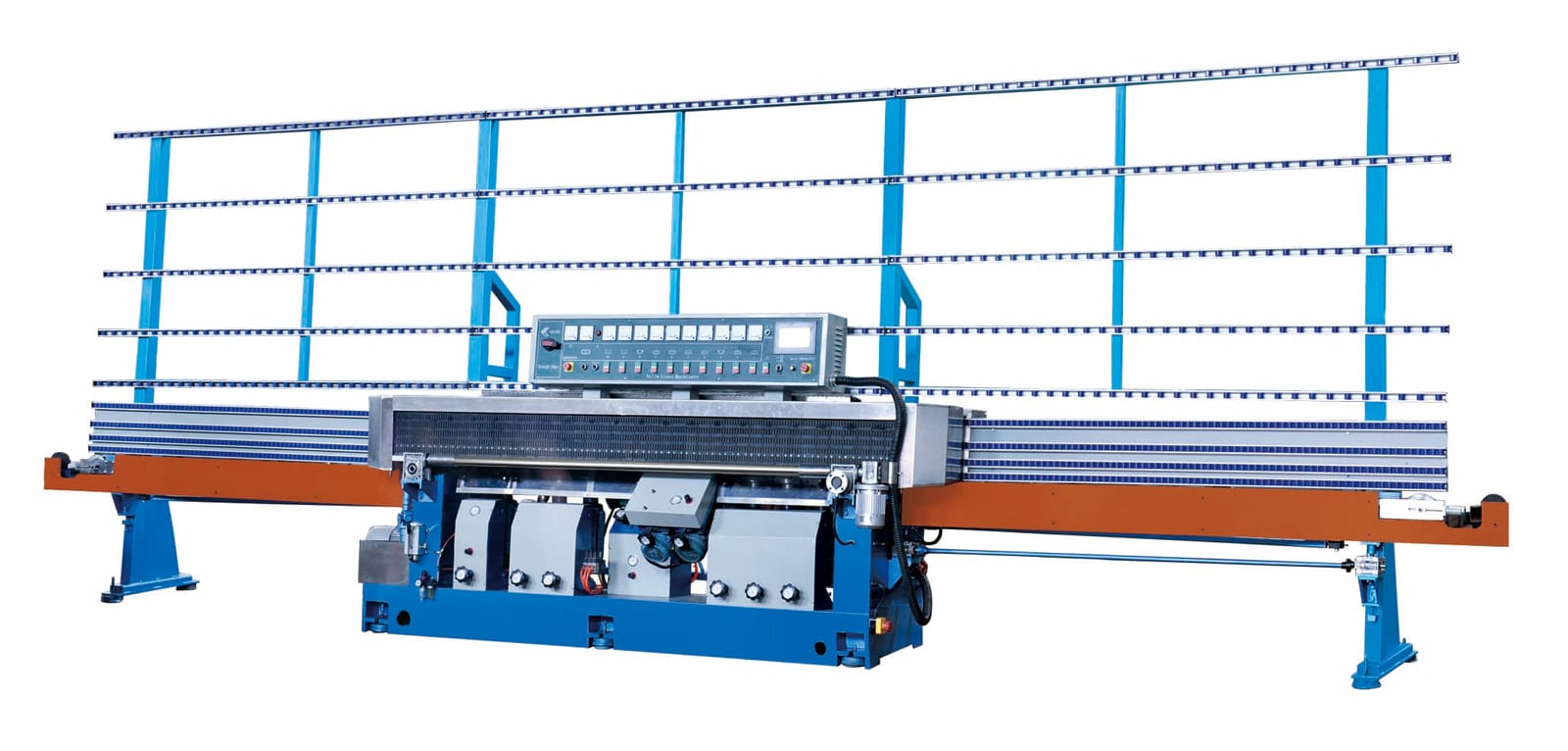

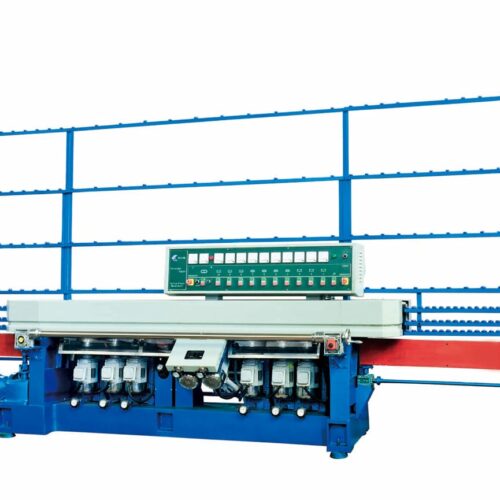

SELIM SE10A Straight Line Glass Edger

Description

Introducing the SELIM SE10A Straight Line Glass Edger, a top-tier machine designed for precision and efficiency in glass edging. Manufactured by SELIM GLASS MACHINERY CO, the SE10A is equipped with 10 spindles, including 2 diamond, 2 resin, and 2 polishing spindles on a 0-45° mitering base, along with 4 spindles for front and rear arris. This advanced glass edger utilizes pneumatically lifted polishing wheels to deliver a flawless, high-quality finish.

Key features of the SELIM SE10A Glass Edger include:

- PLC-controlled spindle positioning for precise adjustments.

- Touch screen interface for setting and displaying glass thickness, miter angle, flat edge width, and conveyor speed.

- Precision cast alloy conveyor with enclosed bearings for smooth operation and high loading capacity.

- Durable timing belts on inlet and outlet conveyors for long life and accurate performance.

- Variable frequency inverter drive to control conveyor speed, ensuring low maintenance and rapid speed adjustments.

- Adjustable inlet conveyor height for quick changes in glass removal during flat polishing.

Experience unparalleled performance and reliability with the SELIM SE10A Straight Line Glass Edger, the ultimate choice for all your glass edging needs.