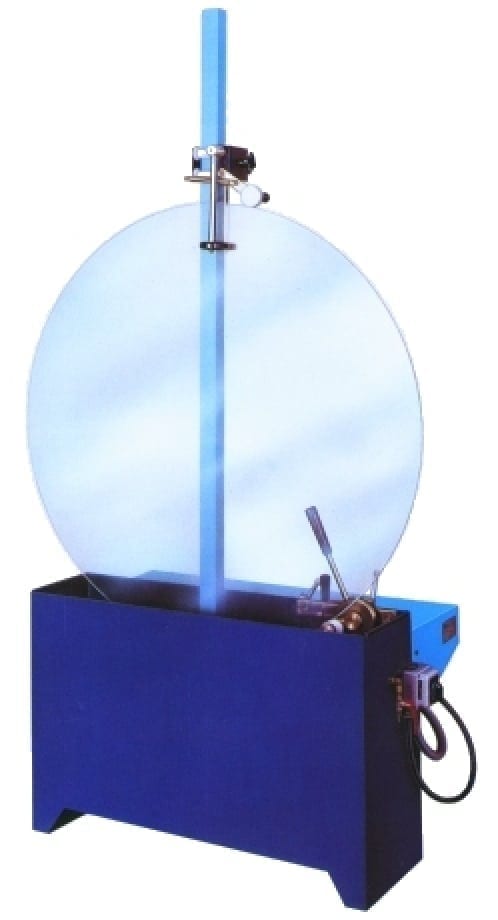

Metral CC Circle Grinder

Description

Specifications:

Diameters from 16″ to 47″ (400-1200mm)

Thickness: 3/16″ – 1/2″ (5-12mm)

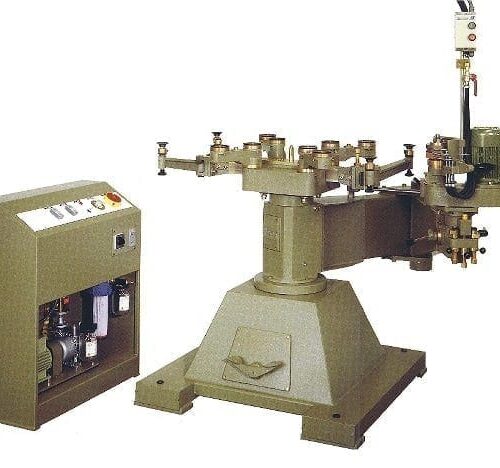

Wheels:

Wheels are single stage (medium grit) diamond wheels 150x22mm

Polishing wheels are 150x22mm bore

Machine dimensions:

Length/width/height: 1.1m x 0.7m x 2.2m (43.3″x22.5″x88.7″)

Electrical:

Grinding motor: 1.5HP 3 phase 60 cycle 220 volt

Drive motor: single phase 220 volt

Pump: three phase 220 volt

The machine works with glass in a vertical position, located on the rubber drive wheel and held above by the adjustable double roller clamp. The drive wheel causes the glass sheet to rotate over the face of the diamond wheel (or polishing wheel according to stage of the process). The weight of the glass keeps the glass in contact with the diamond/polish wheel. The weight is offset by the front v wheel which also represents a contact point with the glass. The V wheel can be adjusted to provide a lighter or heavier grind. On smaller circles (i.e. with less weight) the pressure roller on the upper guide group creates downward pressure on the glass to maintain good contact with the drive wheel and grinding wheel.

Glass placed in the machine must be aligned correctly with the diamond (or polish) wheel. A side shift adjustment with a locking device allows the wheel to be aligned correctly. The diamond wheel is mounted next to the polishing wheel. Make sure wheels are properly clamped on the shaft.

The front V wheel system is adjustable with a lever. To begin the grinding operation use the lever to lower the glass onto the grinding wheel and locate at a suitable grinding level. To finish the grinding operation, use lever to lift the glass off the grinding wheel and then stop the machine. Similarly, if the glass is not cut well or requires several revolutions, use the lever of the adjustment group to decrease grinding pressure on the glass. Thicker glass will require generally at least two revolutions of the glass to grind the edge uniformly.